Industry 4.0 has brought about major technological advances in manufacturing and production. With the advent of the Internet of Things (IoT), artificial intelligence (AI), and advancing automation, companies now have the opportunity to transform their operations and significantly improve the customer experience.

In this article, we will explore the opportunities to accelerate digital transformation and optimize the customer experience in Industry 4.0. I exchanged on this topic with Anthony Durand, Digital Customer Experience Manager at Desoutter Industrial Tools.

Industrial Retrospective

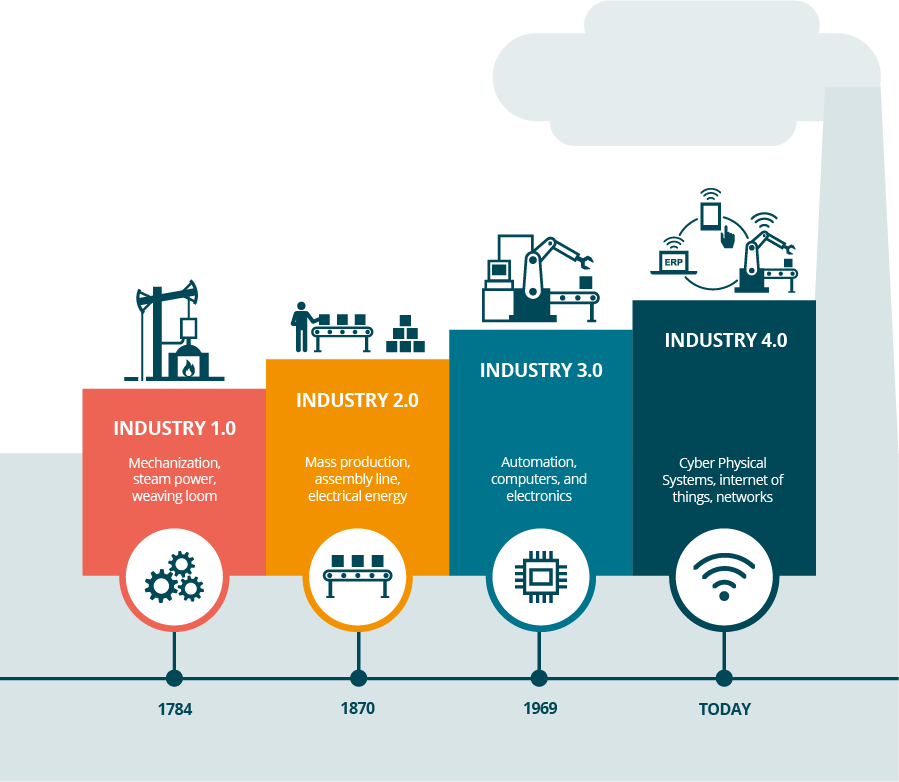

Industry 4.0 is the fourth industrial revolution characterized by the integration of advanced digital technologies into manufacturing and management processes. This new era of industry is characterized by the emergence of smart and connected factories, in which cyber-physical systems and communication via the IoT play a central role.

To understand Industry 4.0, it is important to look back at the previous industrial revolutions. The first revolution was characterized by mechanization, which used water and steam to power machines. Then, the second revolution introduced electrical power, which enabled mass production in factories. The third revolution was marked by the advent of computers and automation, where machines began to perform repetitive tasks on their own. Today, industry 4.0 and digital transformation are driving innovation and reshaping the manufacturing landscape.

What is Industry 4.0 and how does it impact digital transformation in manufacturing?

Today, we are witnessing a fourth major transformation: Industry 4.0. This new era is characterized by the integration of innovative technologies such as artificial intelligence, data analytics, IoT, augmented reality, advanced robotics and 3D printing. These technologies are being used to create truly intelligent production facilities that can communicate with each other and optimize production processes autonomously.

The digital transformation to Industry 4.0 means a shift towards intelligent manufacturing processes. According to management consultants McKinsey, Industry 4.0 is being driven by four key technology trends:

1. Explosion of data volumes

As sensors and connected devices proliferate, companies have access to a massive amount of data. This data can be used to make informed decisions and optimize operations.

2. Data analysis and business intelligence

Advances in data analytics technology enable companies to extract valuable information from the vast amounts of data they collect. With the help of business intelligence, strategic decisions can be made based on these analyses.

3. New forms of human-machine interaction

Industry 4.0 introduces intuitive touchscreen interfaces, augmented reality systems and wearable devices that simplify interaction between people and machines. This enables better collaboration and more efficient use of technologies in the industrial environment.

4. Improvements in the transfer of digital instructions to the physical world

Advances in advanced robotics and 3D printing make it possible to transfer digital models and instructions directly into the physical world. This facilitates custom production, rapid prototyping and automation of repetitive tasks.

What opportunities does Industry 4.0 offer us?

For companies operating in the B2B commerce sector, Industry 4.0 offers numerous opportunities. Production processes are becoming more agile and flexible, enabling greater personalization of products and services. In addition, companies can use Big Data to make informed strategic decisions and increase their operational efficiency.

One of the most important aspects of the digital transformation in Industry 4.0 is the integration of the IoT. Connected objects enable companies to collect real-time data from their plants, machines and products. This connectivity offers significant benefits in terms of operational efficiency and informed decision making. For example, sensors embedded in machines can provide valuable information about performance, predictive maintenance and potential problems. This allows companies to optimize production processes, reduce downtime and improve product quality - all in real time.

Industry 4.0 and AI

Artificial intelligence is another pillar of digital transformation in Industry 4.0. By leveraging the big data that the IoT collects, companies can use AI to analyze, predict and automate processes. For example, machine learning algorithms can be used to optimize supply chains, predict customer demand, and tailor offers to individual preferences. Artificial intelligence can also be used to automate repetitive tasks and improve the overall efficiency of operations. As a result, companies can reduce costs, increase productivity and offer higher quality products and services.

More about search and recommendations

The advantages of personalization

Another crucial aspect of the digital transformation in Industry 4.0 is the improvement of the customer experience. Thanks to technological advances, companies can now offer highly personalized and tailored customer experiences. For example, data collected by the IoT and analyzed by AI can help companies understand customers' individual preferences and provide them with specific offers and recommendations. AI-powered chatbots and virtual assistants can also provide around-the-clock customer support, answering questions and resolving issues immediately. These improvements to the customer experience can strengthen customer loyalty, increase satisfaction, and lead to sustainable business growth.

More about personalization in B2B e-commerce

Which industries are already benefiting from Industry 4.0?

The advantages of using innovative technologies are obvious. Let's take a look at two industries that are pioneers when it comes to Industry 4.0.

The automotive industry

In the automotive industry, Industry 4.0 offers many advantages: First of all, it enables the reduction of system downtime, ensuring optimal production continuity. Through automation and resource optimization, Industry 4.0 increases productivity while reducing maintenance costs. In addition, thanks to agile processes, automotive companies can improve their competitiveness and discover new sales opportunities. Finally, predictive maintenance plays a crucial role, making it possible to anticipate equipment and system failures, correct inefficient developments, and increase productivity.

The aerospace industry

In the aerospace industry, OEMs (original equipment manufacturers) are seeking to increase the overall efficiency of their processes, reduce quality costs and cycle times, and eliminate human error. Smart assembly tools and digital networks play a crucial role in this quest for greater efficiency. They offer greater flexibility and can be fully linked to each other and to manufacturers' production and quality systems. Thanks to these innovations, the aerospace industry can improve its processes, ensure high quality standards and meet the complex requirements of its customers.

These two case studies show how Industry 4.0 is transforming industrial sectors by opening up new opportunities and increasing their competitiveness. Through the integration of advanced technologies and an approach focused on connectivity and automation, Industry 4.0 promises to revolutionize the way companies function and interact with their environment.

Industry 4.0: the future is now

In summary, digital transformation in Industry 4.0 offers unprecedented opportunities to improve operational efficiency and customer experience. The integration of IoT, AI and other advanced technologies enables companies to collect and analyze data in real time, optimize production processes and personalize offerings for customers. However, to make this transformation successful, companies must invest in the necessary infrastructure and capabilities. By accelerating digital transformation, companies can remain competitive in an ever-changing world and deliver a compelling customer experience in the digital industry in Industry 4.0. If you would like to hear how Desoutter is already benefiting from new technologies, you are very welcome to watch the webinar here (in French).