The pandemic-triggered shift to remote work was swift and sweeping, and it appears this trend is here to stay.

A 2020 Gartner survey found that 82% of company leaders plan to let their employees work remotely some of the time, and 47% say they will be implementing full-time remote work. A 2020 McKinsey survey indicates that most businesses expect to implement a hybrid model, with employees doing a mix of remote and on-site work.

Although the shift was meant to help companies survive amidst lockdowns and other restrictions, there is evidence that remote work may actually help businesses thrive: 85% of respondents in an IWG study say their organisation’s productivity increased because of remote work; 65% say they’ve reduced capital expenditures and are better able to manage risks because of flexible working arrangements.

Employees also benefited from remote work as companies quickly implement tools and processes to help teams stay connected. Schedule flexibility and fewer distractions from the open-floor plan workspaces are the added perks from working remotely. Messaging platforms facilitate communication between team members, and team members learned how to communicate effectively at a distance. This enhanced communication has fortified company cultures, leading to enhanced trust, allowing creativity and innovation to grow.

The future is here: why remote work in manufacturing is now possible

At first glance, remote work, digitalisation, and manufacturing seem irreconcilable. Most companies face three significant challenges:

-

- How to remotely monitor production performance and health

- How to get precise insights on machine performance and what needs to be fixed, improved, or adjusted

- How to give on-site teams real-time support and help them become more autonomous

But the truth is that the technology to overcome these challenges already exists. There just hasn’t been a business case strong enough to convince organisations to invest in them until now.

To remotely track production performance and what’s happening in their factories, some manufacturers already use monitoring systems with dashboards showing critical metrics in real-time.

Manufacturers could also leverage artificial intelligence (AI), the internet of things (IoT), and remote collaboration technology to check machine health and assist on-site teams. These enable the remote management of digital machine health, which lets maintenance, operations, and reliability teams monitor its performance without being on-site. This also gives corporate management increased visibility and the ability to collaborate with on-site teams.

To further digitalise and directly control production remotely, manufacturers could also deploy remote workbenches inspired by robotic surgery. By using robotics, high-speed remote communications and terminal access, remote control systems, and virtual or augmented reality, manufacturers could control workbenches without being at their factories.

Additive manufacturing (3D printing) and Model-Based Systems Engineering (MBSE) are another exciting new frontier that could power remote production. Companies in manufacturing, design and engineering can implement remote work and have a distributed workforce by using cloud-based CAD software, virtual prototyping, and virtual verification tools.

By using additive manufacturing, or 3D printing, the factory of the future could allow distributed teams to design parts, test their performance, and then produce these at scale with minimal human intervention. This will shorten development time and streamline supply chains.

"To make the most of these innovations,

companies must invest in upskilling their teams."

First, figure out which teams can work remotely and which ones need to be on-site. Many manufacturers are training their on-site teams to become better generalists, so they can address various issues that may arise at the production site, and training their remote teams to become specialists, so they can better guide remote teams across several sites. Workers then need to be trained to use the new digital tools that their organisations will be deploying.

The upfront costs of tools and training may be intimidating at first, but the efficiency gains, cost savings, and increased resilience you’ll experience down the line will be worth it.

How manufacturers are digitalising and embracing remote selling

Another way B2B companies, including those in manufacturing, are going virtual is through remote selling.

In 2020, the e-commerce sector grew significantly. This growth reflects consumer purchases and B2B transactions, with wholesalers and manufacturers listing their products online.

Moving forward, the three main remote selling models that B2B companies must be prepared to support are:

-

- Self-service

- Assisted commerce

- Full-service commerce (which involves a sales representative)

In the past year, many sales and customer support representatives used e-commerce platforms as tools to help their customers make a purchase. In fact, according to a 2021 Forrester report, 24% of all global B2B transactions were made through assisted e-commerce.

Aside from trying out remote selling for the first time, many B2B companies also learned that they must find the right tools for the job now that optimising for digital is a business imperative.

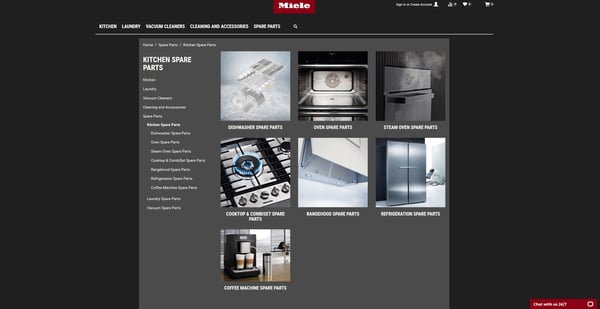

Mira Gladovic, Digital Marketing Manager, Miele Australia, says, “We saw a massive uptick from our digital customer touchpoints such as the e-commerce website, live chat, and virtual consultations in the past couple of years. Our support teams have had to adapt to handling more inquiries and different types of questions. Also, our sales team had to utilise our e-commerce websites which offered virtual Miele Experience Centre visits.”

Gladovic continues: “Having these tools, many of which we had already implemented before the pandemic, has helped us better support our homebound customers in either replacing appliances or renovating their kitchens and laundries. With fewer holidays being taken, it has meant that many consumers have instead focused on home renovations.”

Miele Australia e-commerce website

Miele Australia Experience Centres

Manufacturer digitalisation tips on where to start

For those in the early stages of their digital transformation, all-in-one solutions seem to be the best fit.

Intershop Commerce Management platform, for instance, offers powerful e-commerce essentials all in one place. The unified platform gives you full access to your sales channels and various touchpoints, customer content and targeted promotions, product information, order management, customer engagement tools, and data-driven business intelligence.

Aside from all-in-one digital solutions, other tools that could help manufacturers prepare for these three remote selling models allow for unique personalisation and quick deployment.

Headless Infrastructure offers an API-based architecture that allows for powerful customisation and works for any touchpoint. This approach decouples the frontends from the back office. This means faster time-to-market, granular customisation without affecting the entire system, and omnichannel support that works with voice commerce and progressive web apps.

For a quick, easy, and cost-efficient way to do remote selling, Intershop also has Progressive Web App (PWA) builders that let you achieve the look and feel of a native app without having to actually build one. This eliminates the need to develop separate apps for different operating systems. Instead, you create one web interface that runs smoothly across digital devices— smartphones, desktops, and tablets. You can also get this from Intershop as a template straight out of the box. All you need to do is customise based on your corporate identity, add your products, and business rules.

Be digital-ready and future-proof with Intershop

Disruptions, whether natural or man-made, can happen without warning and can derail any operation. But manufacturing companies and other industries that rely heavily on physical processes are significantly more vulnerable to these interruptions than other industries.

Fortunately, a growing list of digital tools and B2B e-commerce strategies make virtual manufacturing work possible. By putting remote work and remote selling systems in place today, you’re preparing your company to be more flexible in the future.

To learn more about how e-commerce tools can help manufacturers and wholesalers digitalise and transform their business, request a demo with Intershop today.