Products are no longer purchased, but rented, leased or shared. Manufacturers will sell not only products but also services in the future. Portfolios that bundle product use with maintenance and service are a viable option here.

To implement this, companies need cross-departmental innovation projects involving production, IT and not least sales. After all, it's not just about making products "smart" in the cooperation between production and IT. It's also about innovative service and payment formats, new bundles and the corresponding processes. That's why the sales department also has to be involved in the project. Exciting impulses come from the e-commerce environment on the subject of pay-per-use and product-as-a-service.

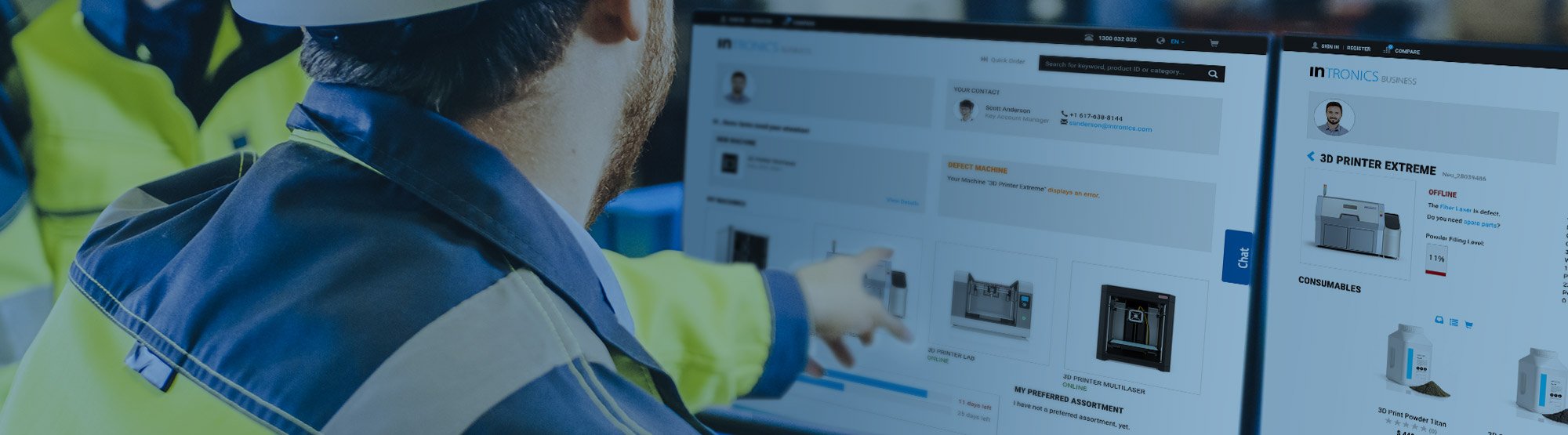

Intershop's Smart Drill

We have created our own show case for pay-per-use: A drill, that is not sold, but billed according to the pay-per-use method. In this case, billing takes place promptly, in our example using a crypto currency on the basis of upfront payments. In order to start the machine, the user pays an amount into his or her account (in crypto currency). The drill can be adjusted to three different capacity levels. It reports utilization and speed in real time to the e-commerce platform, which in turn translates these figures into the intensity of use and debits them to the crypto account - all this in real time.

The advantages are obvious: no investment is required on the customer side. The customer has no capital commitment, he or she can scale freely up and down. The supplier in turn has fast access to the market. He does not have to argue the ROI for higher investment sums. Suppliers and demand come together faster because there is no investment risk for the customer. The cash flow is guaranteed.

What's more, the supplier always knows where the device is. Thanks to the location information also integrated into the drilling machine. And last but not least, the sensor data can be used for predictive maintenance concepts.